Ring Frame or Doubling Machine

Ring frame spinning machines are a well-known machinery among the textile industrialists revolutionizing the industry standards completely. The cloth you are wearing right now is fabricated through multiple processes, from obtaining it through the source to outsourcing it to wholesale dealers of the textile industry. While several processes are included in delivering you the right quality of cloth, one of the major procedures is twisting the fabric to achieve the yarn and this takes place through the advanced mechanism. Ring frame machine or textile doubling machine opts for the latest technologies for spinning the yarn which is then rolled onto the bobbins for storage purpose, making it one of the most successful tools in the industry.

Benefits of using a Doubling Machine

One of the prime doubts of industrialists while investing in the vast machinery is whether it is worth that amount or not. Several factories upgrade their age-old spinning techniques to the latest ring spinning mainly because it offers tremendous advantages.

High Tensile Strength : The technique adopted by the textile doubling machine mainly accounts for making the strength of the yarn better. Several testing methods are used to determine the strength of the yarn and previous studies show that yarns made by the latest spinning methods turned out to be the strongest. This can improve the industry standards of the manufacturers yielding better leads.

Lustrous And Uniform Yarn : The freshly obtained strands are uneven and have a rough surface. The prime reason for twisting is to make the yarn smooth and ideal for further bobbing, and the requirement is fulfilled by using a quality ring frame.

These are a few of the advantages, but the list is endless. One cannot finish stressing on the usefulness of textile doubling machines because of its several benefits which have been helping industrialists to produce prime quality yarn, improving the reputation of the respective manufacturer.

How Much Does A Doubling Machine Cost?

Ring spinning machines cost around 1,00,000 and this price can go as high as 10,00,000. There are two types of machines available in the market- semi-automatic, and fully automatic. Since manufacturers have varied requirements, buying spare parts is considered beneficial which can provide additional features to the machine once it is assembled. As disparate kinds of yarns require different treatments, assembling according to the requisites can yield substantial profits for the textile industrialists.

We are happy to let you know that we are renowned textile traders in the industry offering impeccable services for 30 years now by supplying spare parts of the ring frame spinning machine at reasonable prices.

Our expert team closely monitors the dealing and exporting while maintaining the current industry standards. We offer a wide range of spare parts, including:

Alluminium Sepretor

Leather Belt

Spindle Tape

Sandwitch Belt

Rubber Socket

Piston Set

Knee Brake

Joint Coupling

Roving Guide

Sliver Guide

Condensor

Any Type Spindle lock

Alluminium or MS Rivit

Jockey Pulley all type

Jockey Pulley cover

Drum Pulley

Cap Bar finger (All sizes)

Suction pipe

End bush for Nemafil Pipe

Suction Tube Coupling

Suction Air Socket

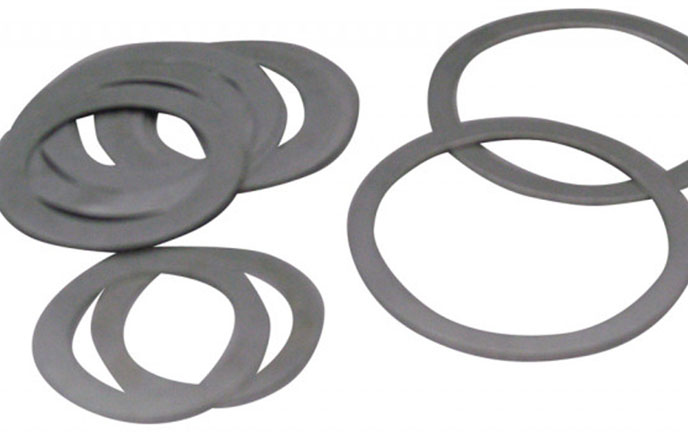

Shim Washer Roller Gauge

Plastic Seperator

This is by far the most asked question of the manufacturers. There are several aspects of the doubling machine, the most important being the number of spindles and drafting rollers accountable for the actual process of twisting novel kinds of material like cotton, wool, polyester, etc.

The drafting rollers that are responsible for the productivity of the machine are generally connected with the attenuated rover through which the thread is passed.

Not going into the complex process of twisting and getting the required fabric, you must make sure that the machinery for this process is in pleasant condition for long-term use.

Final Thoughts

Ring frame spinning machines have always been one of the favourite tools of the manufacturers and buying one is a long-term investment. One should always keep all the factors in mind while going for an enormous machine or its spare parts. Quality of spare parts and machine should not be compromised to maintain the premium nature of the fabric.