Simplex Speed frames

Simplex frames have a substantial importance in the textile industry when it comes to obtaining complete fibres from a raw source. Simplex frame or fly frame is a huge contribution in the spinning process. The basic purpose of the simplex frame is to attenuate silver to roving or thin strands of yarn with a considerable amount of twists. Let’s break the information and understand the complex machinery.

Procedure And Apt Functioning Of Simplex Frame

The three basic procedures are followed in a simplex frame.

Drafting : This is the first step in the spinning process through the simplex machine. The raw fibre collected is commonly thick with high linear density. The loose and uncombed raw fibres are passed through drafting rollers with each rotating at a faster rate than the previous one. These drafting rollers are devised to achieve a low density of loose strands by making them thin and straight. The outcome of drafting is called roving.

Twisting : Next in the process is twisting. Roving is ideal to put a certain number of twists to increase the strength of the yarn. Two types of twists are put up in every fabricated yarn S and Z. Twists refer to a limit of a number of turns per unit length. It is important to note that the strength of a yarn is increased only up to a particular number of twists and if exceeded, it can instead prove to be harmful to the quality of the yarn and decrease its strength.

Winding : The last step includes winding the obtained yarn on to the bobbins. The rolls are then checked for quality by the respective experts and sent out to the retailers and wholesale dealers.

Thus, the simplex process in spinning comprises these three basic processes. It is important to conduct these righteously to get the premium quality of the fabric.

Common Parts of Simplex Frame

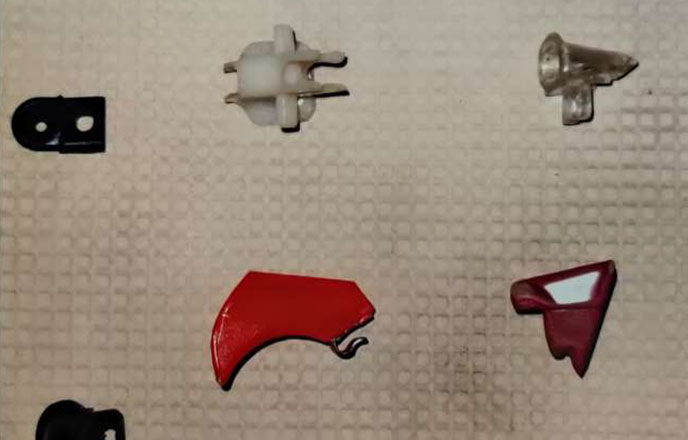

The common simplex machine parts include:

Needle Bearing Cage

Bearing cover

Top Arm Clamp Retainer

Craddle Spring

Pressure setting Patti

Twist Master

Jockey Pulley Bracket

Bobbin pin

Flyer screw all type

Roving Guide

Sliver Guide

Condensor

Cradle Saddle Spring

These parts are fairly common and fitted in the complex machinery of the simplex frame. For the smooth functioning of the simplex frame, it is necessary to include premium parts while manufacturing the machinery.

Several other parts can also be fitted in the machine to upgrade the quality which can yield better outputs.

To ensure a long life of machinery, some additional parts along with appropriate care are necessary and one should not compromise on that.

Conclusion

Simplex frames are an important aspect of the spinning process, and so are its parts. It is important to choose the right machinery and set it up according to the fibre. The three basic processes should be conducted with absolute precision and intensive care for the premium quality fibre. While taking all the measures, it is also necessary that you maintain the simplex frame properly with regular oiling and greasing to ensure longevity as it is an onetime and long-term investment.

We at Arihant Textile Traders are here at your service providing quality products for 30 years. We deal in all novel kinds of simplex machine spare parts as well as for various other frames used in spinning processes like Ring Frame, TFO Machine, Winding Machine, to name a few. Our impeccable services have now set up as a global brand in the textile industry. Our expert team closely monitors all the procedures while maintaining the current industry standards. We are self-sufficient for providing exemplary export services to different sweeping manufacturers and small-scale industrialists at a reasonable price. To get the best quote, connect with us here.